SEAT starts the production of emergency ventilators at its Martorell facilities

SEAT has started the production of emergency ventilators at its Martorell facilities to contribute to the fight against COVID-19. The device has been authorised by the Spanish Agency of Medicine for clinic investigation and the daily production volume will be constantly adjusted with the authorities according to demand to avoid unnecessary stocks. The company will work to reach a production volume of 300 emergency ventilators a day at the SEAT Leon assembly line.

The device, called OxyGEN, was free hardware designed by the company Protofy.xyz and under the medical coordination of doctors Dr. Manel Puig Domingo (Germans Trias and Pujol Investigation Institute), Dr. Oriol Estrada (Hospital Germans Trias i Pujol), and Dr. Josep María Nicolás (Hospital Clínic), in a collaborative work against the clock for the past two weeks to make this project a reality.

SEAT President and Vice-president for Finance and IT Carsten Isensee, emphasised that, “responding to the shortage of medical supplies is a priority as well as a responsibility for a company with great industrial capacity like SEAT. Any support is needed now to fight the spread of COVID-19 together.”

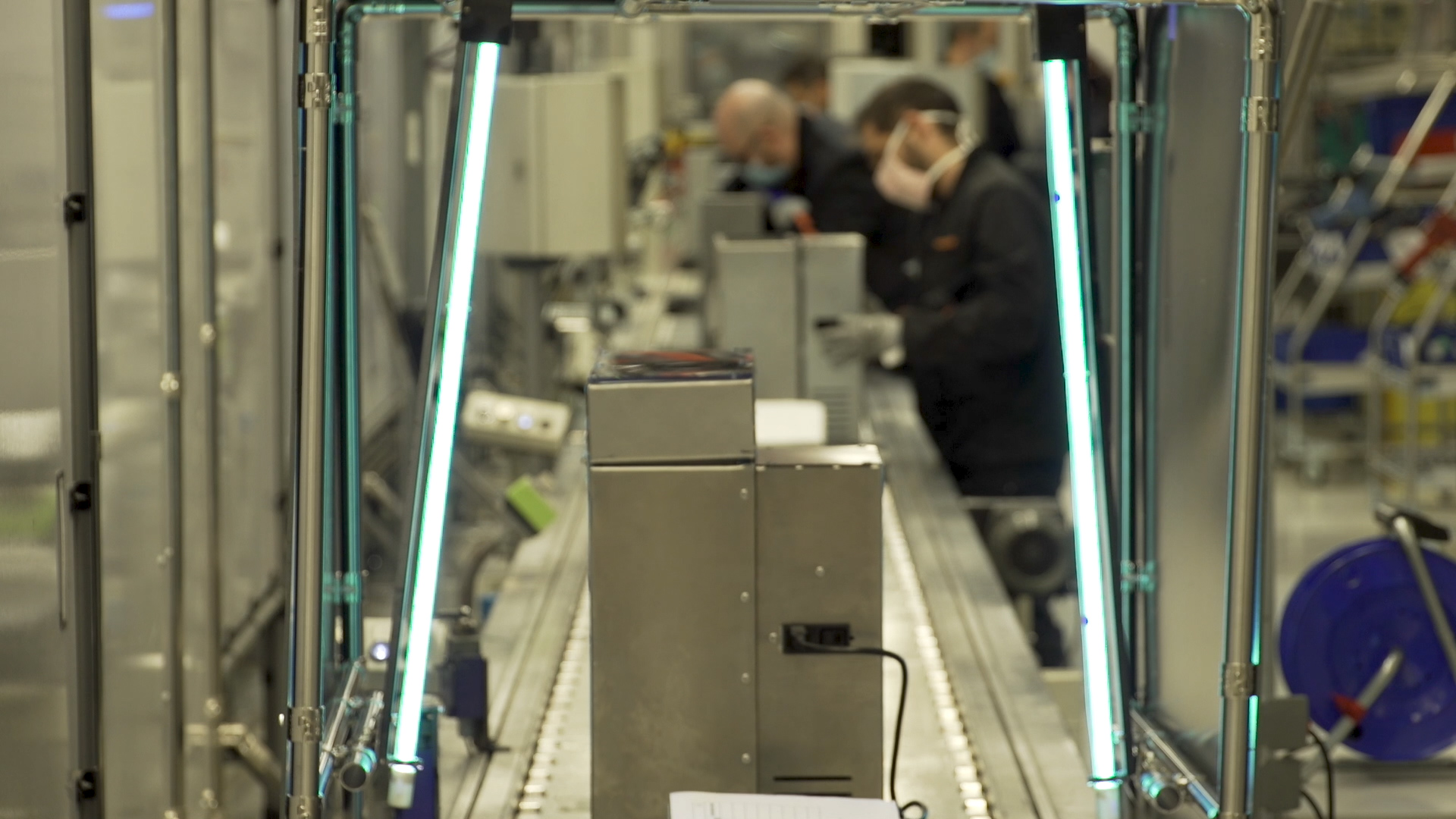

These emergency ventilators are being produced on the SEAT Leon assembly line at SEAT’s facilities and are bring product using adapted windscreen wiper motors. Each device has more than 80 electronic and mechanical components and passes a thorough quality control with ultraviolet light sterilisation.

SEAT Vice-president for Production and Logistics, Dr. Christian Vollmer, who is leading the project pointed out that, “teamwork and collaboration is now more important than ever so that together we can try to meet the demand from health centres. At SEAT we have an advanced mass production system and in a situation like the present one it is our responsibility to make it available to Spanish society.”

SEAT Vice-president for Legal Services and Good Governance Luis Comas stressed that “this process would not have been possible without the support of the Spanish Agency for Medicines and Healthcare Products and the personal involvement of its director and the Spanish minister of health.”

SEAT is strongly committed to helping the health system and professionals in every way possible to slow down the spread of COVID-19. SEAT is also currently working on and analysing the viability of other projects that will be announced once they have passed all the necessary health tests and cleared for release by the corresponding authorities. To this end, a team of professionals from the areas of Production, Health and Emergencies, Development, Logistics and Quality, among others, have been working against the clock for the past two weeks to make these projects a reality.

Entities collaborating on the development of the emergency ventilator

Protofy.xyz

OxyGEN

Hospital Clínic

Hospital Germans Trias i Pujol

Germans Trias y Pujol Investigation Institute (IGTP)

Hospital del Mar

CMCiB (Catalan Centre for Comparative Medicine and Bioimaging)

University of Barcelona

Recam Laser

Doga Motors

Luz Negra

LCOE (Official Central Automation Laboratory)

Ficosa

Bosch

IDNEO

Secartys

Espiroflex

Gaso

Cuatrecasas

Civil Guard

Urban Guard

Mossos d’Esquadra

National Police

From making cars to ventilators

- SEAT is collaborating with the Spanish healthcare system by making automated ventilators with adapted windscreen wiper motors

- 150 employees from several areas of the company have worked for a week on the definitive model after designing 13 prototypes

- A ventilator is currently undergoing extended testing as part of the approval process

The SEAT Leon line at the Martorell plant is almost unrecognisable. Today, cars are no longer being manufactured, instead, automated ventilators are being produced in collaboration with the Spanish healthcare system in the midst of the COVID-19 crisis. Going from producing cars to ventilators in record time is the result of the intense work of many SEAT employees and a very powerful driving force: solidarity. “The motivation of everyone participating in this project is that with our know-how we can mass-produce equipment that will save lives”, explains Nicolás Mora from the Production area of SEAT Martorell.

Ongoing activity

Since the beginning of the COVID-19 Crisis, several initiatives have been launched at SEAT to combat the spread of the virus. Specifically, to produce material and devices in high demand by hospitals, such as ventilators. A team of engineers diligently set about designing several prototypes, 13 in all, until the definitive model was produced.

The key lies in the windscreen wiper

The aim was to make ventilators of the highest quality and this is being done with gears printed at SEAT, gearbox shafts and the adapted motor of a windscreen wiper. These ventilators designed in collaboration with Protofy.XYZ and are being assembled at the SEAT facilities.

Transforming the assembly line

150 employees from different areas of the business have changed their usual workstation to put together the ventilators where parts of the SEAT Leon used to be assembled. “Taking an assembly line that manufactures subframes, a car part, and adapting it to make ventilators has been a lengthy, difficult job involving many areas of the company, and we managed to do it in the record time of one week”, says Sergio Arreciado from the Process Engineering area of SEAT. Each ventilator has more than 80 electronic and mechanical components and undergoes a thorough quality control check with ultraviolet light sterilisation.

Quality tested

The ventilator is currently undergoing prolonged testing as part of the approval process. Meanwhile, the line continues to operate thanks to many employees who have worked tirelessly on this project. “Just knowing that we’ve tried to help save a life makes all this work we’ve done worthwhile”, says Francesc Sabaté of R&D at SEAT.

Joint effort

The result of this project has been possible thanks to the solidarity of its employees and the collaboration of many companies* and entities that SEAT would like to thank for their involvement, especially the Spanish Agency of Medicines and Healthcare Products.